It will be ready soon!

The main supplier of robotic stations for noodle production. The robots have dared to grab bowls! A restaurant with an extraordinary technological motif, where one can get an interactive experience and eat well. Have a visit and enter the era of an intelligent future.

01 Introduction

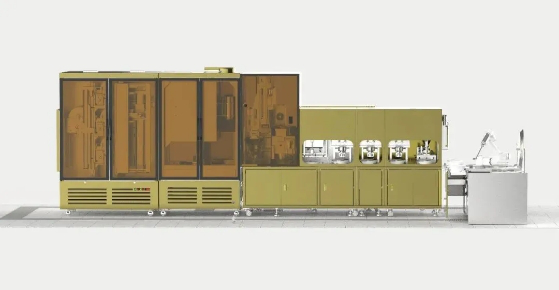

Just 3 years ago, the Allove company wished to combine the concepts of “cooking fresh noodles” and “robot swarm”, using new ideas, technologies and models to create the first “autonomous” noodle restaurant in China, integrating the kitchen with the Internet. The intelligent, autonomous experience they have developed begins when you cross the threshold of the restaurant – after you sit down at a table, the menu is available by scanning a QR code, and you can place an order independently. Next, meals are cooked and served using only robots. Noodles are available in optional variants, cold dishes are unchanging, tea and coffee are served hot, and if you prefer something cold, check the offer of beverages. Two mobile food trolleys are responsible for serving meals and beverages. How can the critical process of cooking noodles be performed using the standard operations of automated equipment? All this while simultaneously preserving the impression of closeness to technology?

02 Problematic issues

- Dough production robot

- Dough packing robot

- Dough storage and collection robot

- Robot for cooking fresh noodles

- Bowl disinfection and distribution robot

- Bullion and sauce dosing robot

- Robot for arranging vegetables and toppings

- Robot for cooking bullion and toppings

During the first stage of noodle production, storage and cooking, the client indicates a set of mechanisms that make it possible to carry out a series of operations fluidly. At the second stage – serving and distribution, the client sees the ingredients that are collected and cooked, as well as additional requirements related to the food’s presentation, so operations cannot be performed in a “short and sweet” way. They must be carried out by flexible equipment, which is why the client is choosing collaborative robots.

03 The Solution

Light weight, an attractive appearance and compact dimensions are features supporting the choice of products of this type. The ELITE EC66 collaborative robot (6 kg) weighs just 17.5 kg and can be installed at any table, occupying only a small space. Moreover, each of the robot’s 6 joints allows for ±360° rotation, increasing the flexibility of movements and ensuring the absence of deadzones. Thus, it is capable of decorating freshly cooked noodles by performing agile and fluid movements, adding “soul” to a bowl of machine-prepared noodles.

“Programming collaborative robots is easier than we expected. ELITE robots support drag-and-drop software, demonstration programs and interactive software at the computer level, which was an unexpected discovery during our integration process. Thanks to the fact that engineering work related to programming and removal of errors was simplified, we were motivated to use the equipment more frequently and fire up our imaginations in this way”. This was the client’s opinion. Currently, the robot is capable of supporting 2 types of toppings. Next, the client plans to apply 2 robots to manage 8 types of toppings, in order to expand the restaurant’s menu further and increase work efficiency.

This bowl of noodles can warm your heart and stomach! Just a minute! There is also a robot arm here that brews coffee!

Take a cup of freshly brewed coffee. It was prepared just for you.

The robot takes a cup, places a capsule in the coffeemaker, and collects a cup of coffee, all in one procedure! During the whole process, no manual operations of any kind are required. Simple and convenient.

You don’t have to wait long for a cup of hot coffee. What about the taste? Two words: “Aromatic! Expressive!” There is a bright future ahead of these robots!